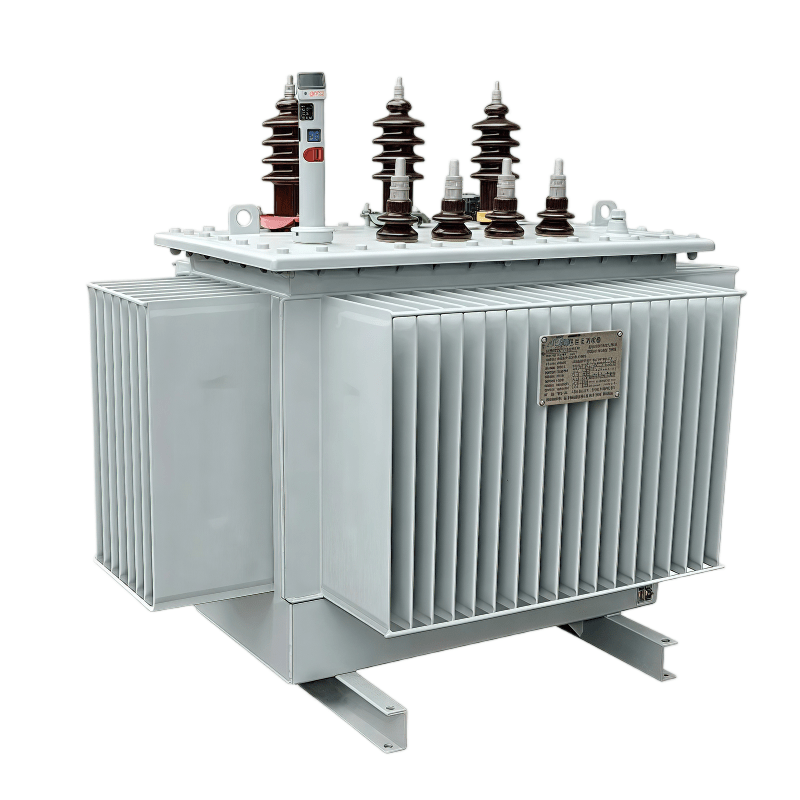

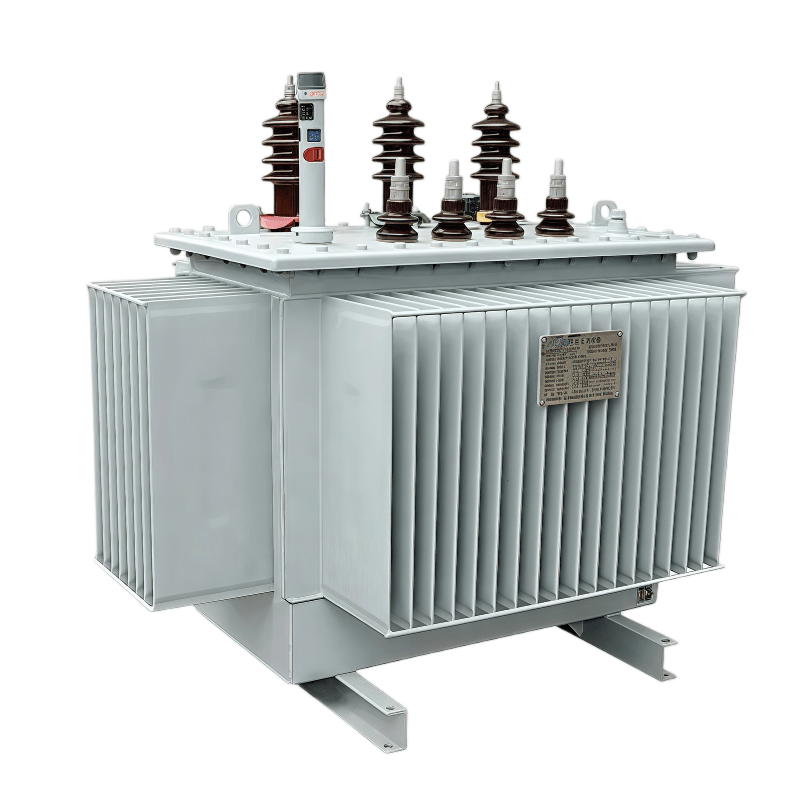

Oil transformers 35 kV TMG

Capacity: 63кВА-2500кВА, 15кВА-315000кВА

Voltage: 6, 10, 15, 20, 30, 35КВ

Row: S9, S11, S12, S13, S20, S33

The company’s S-35kV series oil-immersed transformer is suitable for three-phase AC with a frequency of 50/60Hz and a rated voltage of 35kV in distribution networks, playing an important role in high-voltage transmission and low-voltage power supply. Featuring high efficiency and low loss characteristics, these products can save significant energy and operating costs, while also achieving social benefits. They are widely used in power plants, substations, industrial and mining enterprises, ports, airports, and other places. Equipped with a load tap changer, the product can implement manual or automatic voltage regulation without power failure, helping to stabilize the grid voltage at each load center and improve power supply quality.

Standards

IEC60076-1:2011 Power transformers. Part 1: General.

IEC60076-2:2011 Power transformers. Part 2. Temperature rise of liquid-filled transformers.

IEC 60076-3:2013+AMD1:2018 Power transformers. Part 3. Insulation levels, dielectric tests, and external air clearances.

IEC 60076-5:2006 Power transformers. Part 5. Short-circuit withstand capability.

IEC 60076-10:2016 Power transformers. Part 10. Determination of sound levels.

Normal Environmental Conditions

- Ambient Temperature: No more than +40℃, No less than -25℃, Average Monthly Temperature no more than +30℃, Average Annual Temperature no more than +20℃.

- Altitude: No more than 1000m.

- The power supply voltage waveform is similar to a sine wave.

- The voltage of a three-phase power supply is approximately symmetrical.

- The total harmonic content of the load current should not exceed 5% of the rated current;

- Installation Location: Indoors or outdoors.

Product Features

The core is made of cold-rolled silicon steel sheet with high magnetic conductivity and grain orientation, with low no-load losses.

The three-phase winding is a concentric coil with a corrugated oil channel. Dipping is not used, and the tape is tightly bound. This ensures high mechanical strength, balanced current distribution, and high short-circuit resistance.

A positioning structure has been added to the housing to prevent movement during transportation. All fastenings are equipped with fastening nuts to prevent loosening during long-term operation.

This product is a completely sealed design. Vacuum oil filling is used during packaging, which completely removes moisture from the transformer, isolates the transformer oil from external air, prevents oil aging, and improves its reliability. All capacitor section transformers are equipped with safety valves, and upon customer request, gas relays with alarm and tripping functions can be installed, ensuring safe operation of the transformers.

A corrugated oil tank is adopted. This type of oil tank offers advantages such as ease of processing, high mechanical strength, good welding properties, and no leakage. Moreover, the high fluidity of the oil improves the product’s heat dissipation properties.

The product is attractive in appearance, compact in volume, and has a small footprint. It is an ideal, maintenance-free product.